Hot Stamping Leather

About hot stamping leather

Demand of hot stamping leather has been rising during recent years. It is widely used in book covers, labels, boxes and so on.

Hot stamping leather is also called high temperature embossing color change leather, and our material is PU leather.

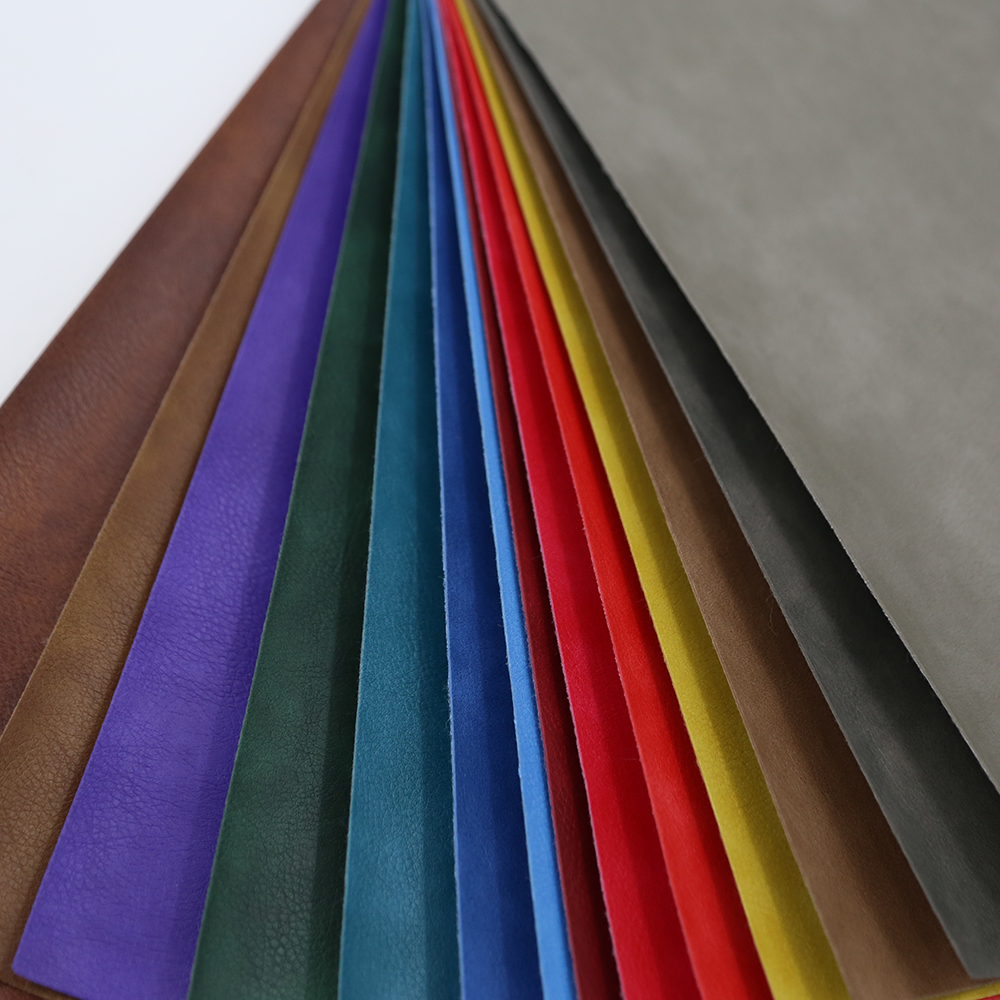

Color of hot stamping leather

The special effect of hot stamping leather is mainly from different colors before and after hot stamping. There are 3 kinds of options: first one is same color with surface color after hot stamping which shows a 3D looking because of depth it makes; second one is same color but darker than surface color after hot stamping of which the visual effect is more vivid; third one is different color with surface color after stamping which has different beauty and sense of dislocation.

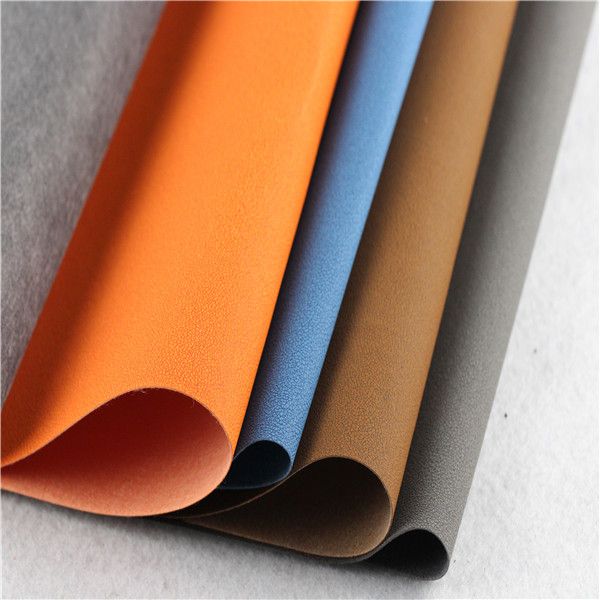

Thickness of hot stamping leather

Besides color, we also receive customer’s various requirements on thickness. For making book covers, like notebook, diary book, album book, agenda book, we will suggest 0.6-0.8mm thickness which is normal thickness. For making labels, like jean labels, jacket labels, bag labels, it usually uses 1.4-2.0mm which is very thick, it will shows the elegant and high-end of labels. For glasses boxes, the leather should be thin so that it can be attached with frame closely. But for jewelry boxes, the leather should be thick so that the touch feeling is soft and has high value looking.

Surface of hot stamping leather

The most classic surface of hot stamping leather is cow leather pattern which is suitable for jean labels and scrolls books if you want a vintage design. And for more fashion designs, we have developed various patterns, for example: crocodile pattern, snake pattern, wood pattern, flower pattern and so on.

Backing of hot stamping leather

With sorts of demands, we have developed kinds of backing fabric of hot stamping leather. Nonwoven backing fabric is most economic. It is normally used on leather of which the thickness below 1.4mm. Microfiber backing fabric is the best options currently; it makes the faux leather approach to real leather in each aspect. And we can change the backing fabric according to customer’s budget and applications.

Design of hot stamping machine

Logo, graphic and words are main elements that be stamped on hot stamping leather. If customer needs to develop new design of hot stamping, we provide customization service. We can both sell raw material hot stamping leather and semi finish or finish products.

Tips of using hot stamping leather

Temperature is the most important factor when using hot stamping leather. We suggest to set the temperature of machine to 120℃. The graphic will be blurry if temperature is too low; and the surface will be damaged if temperature is too high.

Hot stamping leather is one of our product lines, we are welcoming customers to contact us for more details. And we can provide free sample for customers to test. We will provide customized solutions for different customers. So please feel free to contact us.